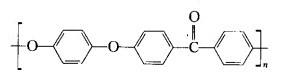

聚醚醚酮(PEEK)是一种主链由芳基、酮和醚键组成的线性聚合物。PEEK的分子链中有大量苯环,因此其耐热性可以与聚酰亚胺相媲美,而两条醚链和一个反叛基团为该材料提供了灵活性和卓越的工艺。其结构如下:

PEEK具有良好的熔体流动性和高于熔点的热稳定性。因此,它具有典型的热塑性加工性能,因此可以采用注塑、挤出、吹塑、层压等成型方法,也可以采用纺丝、成膜等。尽管聚醚醚酮的熔融温度范围为360~400°C,但其热分解温度超过520°C,因此其加工温度范围仍然很宽。

Polyether ether ketone is a thermoplastic substance that was created in 1978. Eventually, it came to market in the 1980s and has seen applications in industries as diverse as below:

Aerospace

Car

Medical

Railway

Oil and Gas

Semiconductor

| Item | Test Standard or Instrument | Unit |

(100%PEEK) PEEK i330G |

(100%PEEK) PEEK i550g |

(100%PEEK) PEEK i770G |

| Tensile strength(23℃) | ISO-527 | MPa | 110 | 100 | 100 |

| Tensile elongation(23℃) | ISO-527 | % | 25 | 40 | 45 |

| Flexural strength(23℃) | ISO 178 | MPa | 175 | 170 | 165 |

| Flexural modulus(23℃) | ISO 178 | GPa | 4.3 | 4.2 | 4.1 |

| Compressive strength(23℃) | ISO 604 | MPa | 130 | 125 | 125 |

| Charpy Impact Strength | ISO 179/1eA | KJ/㎡ | 4 | 6 | 7 |

| Izod Impact Strength | ISO 180/A | KJ/㎡ | 5 | 6 .5 | 7 .5 |

| Melt Index | ISO 1133 | g 10min-1 | 80 | 20 | 10 |

| Item | Product information | model | colour | Basic physical properties/application | |

| 1 | PEEK iPEEK® i330G | i330G | NAT/BLK | Melt Index=80g/cm ,virgin | Download |

| 2 | PEEK iPEEK® i550G | i550G | NAT/BLK | Melt Index=20g/cm,virgin | Download |

| 3 | PEEK iPEEK® i770G | i770G | NAT/BLK | Melt Index=10g/cm,virgin | Download |

| 4 | PEEK iPEEK® i551G | i551G | NAT/BLK | Melt Index=14g/cmImplantable ,virgin | Download |

| 5 | PEEK iPEEK® i551LG | i551LG | NAT/BLK | Melt Index=330g/cm ,virgin | Download |

2024 © Copyright DONGGUAN REDSPOT TECHNOLOGY CO.,LTD. All rights reserved.