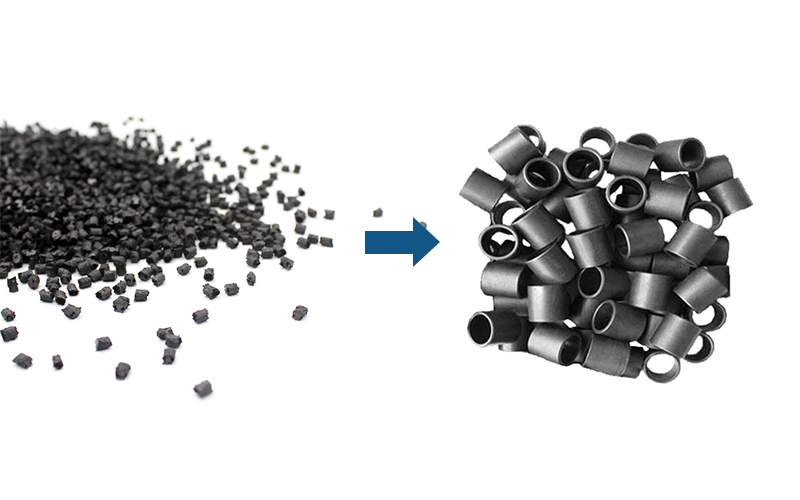

PEEK can be selectively altered by introducing additives or fillers designed to achieve specific characteristics. The resulting plastic compounds offer various (usually increased) thermal, mechanical, electrical, optical or other properties that are improved over those of the unmodified base polymers. In addition to colourants, the most commonly used fillers and additives include reinforcing fibres, stabilisers and friction reducing additives.

Contact us

The most commonly used glass fiber filled PEEK content is 30%. The name of this material in iPEEK® is i770GL30. Compared with PEEK unfilled, the PEEK material filled with glass fiber can improve higher hardness, strength and better heat resistance. The thermal deformation temperature of PEEK filled with glass fiber can be increased from 160 ℃ to over 300℃. Compared with this, the disadvantages of glass fiber modification are that it is more difficult to process, and the toughness and electrical properties are decreased compared with PEEK unfilled.

Typical models: i330GL30, i550GL30, i770GL30, i330GL15, i550GL15, i770GL15, etc

The most commonly used carbon fiber filled PEEK content is 30%. The name of this material in iPEEK® is i770CA30. Compared with PEEK unfilled, the PEEK material filled with carbon fiber can improve higher hardness, strength, better heat resistance and friction characteristics. The modified PEEK filled with carbon fiber can be increased from 160 ℃ to over 300℃. Compared with this, the disadvantages of its carbon fiber modification are that it is more difficult to process, and the toughness is reduced. At the same time, due to the addition of carbon fiber, it has conductive characteristics.

According to the liquidity, it can be subdivided into:

i330CA30,i550CA30,i770CA30,i330CA15,i330CA15,i770CA15;

PEEK HPV is a PEEK material with low friction coefficient and good wear resistance. Among them, PEEK accounts for 70%, PTFE accounts for 10%, graphite accounts for 10%, and carbon fiber accounts for 10%. The name of this material in iPEEK® is i770FC30. The filling of graphite and PTFE can well reduce the friction coefficient of the material, and can still reduce the energy consumption and noise in the use process without using the lubricating medium; The addition of carbon fiber can improve the rigidity of the material. Compared with other brands, its disadvantage is that its brittleness is large, that is, its impact strength is small.

According to the liquidity, it can be subdivided into:

i770FC30,i550FC30,i330FC30

| Item | Test Standard or Instrument | Unit |

(100%PEEK) PEEK i330GL20 |

(100%PEEK) PEEK i550GL20 |

(100%PEEK) PEEK i770GL20 |

| Tensile strength(23℃) | ISO-527 | MPa | 145 | 155 | 155 |

| Tensile elongation(23℃) | ISO-527 | % | 2.4 | 3.3 | 3.3 |

| Flexural strength(23℃) | ISO 178 | MPa | 235 | 245 | 245 |

| Flexural modulus(23℃) | ISO 178 | GPa | 8.5 | 8.8 | 8.8 |

| Compressive strength(23℃) | ISO 604 | MPa | - | - | - |

| Charpy Impact Strength | ISO 179/1eA | KJ/m-2 | 6(Notched ) | 7(Notched ) | 7 |

| Izod Impact Strength | ISO 180/A | KJ/m-2 | 7 (Notched) | 7 .5(Notched ) | 7 .5 |

| Melt Index | ISO 1133 | g 10min-1 | 40 | 11 | 6.5 |

| Item | Product information | model | colour | Basic physical properties/application | |

| 1 | PEEK iPEEK ® i770GL20 | i770GL20 | NAT/BLK | Melt Index=6.5g/cm3 | Download |

| 2 | PEEK iPEEK® i550GL20 | i550GL20 | NAT/BLK | Melt Index=11g/cm3 ,20% glass fiber reinforced | Download |

| 3 | PEEK iPEEK® i550GL10 | i550GL10 | NAT/BLK | Melt Index=12g/cm3 ,10% glass fiber reinforced | Download |

| 4 | PEEKiPEEK® i330GL20 | i330GL20 | NAT/BLK | Melt Index=40g/cm3 ,20% glass fiber reinforced | Download |

| 5 | PEEK iPEEK® i770GL30 | i770GL30 | NAT/BLK | Melt Index=4.5g/cm3 ,30% glass fiber reinforced | Download |

| 6 | PEEK iPEEK® i550GL30 | i550GL30 | NAT/BLK | Melt Index=6g/cm3 ,30% glass fiber reinforced | Download |

| 7 | PEEK iPEEK® i330GL30 | i330GL30 | NAT/BLK | Melt Index=28g/cm3 ,30% glass fiber reinforced | Download |

| 8 | PEEKiPEEK® i770CA20 | i770CA20 | NAT/BLK | Melt Index=4g/cm3 ,20% carbon fiber reinforced | Download |

| 9 | PEEK iPEEK® i550CA20 | i550CA20 | NAT/BLK | Melt Index=7g/cm3 ,20% carbon fiber reinforced | Download |

| 10 | PEEK iPEEK® i330CA20 | i330CA20 | NAT/BLK | Melt Index=31g/cm3 ,20% carbon fiber reinforced | Download |

| 11 | PEEK iPEEK® i770CA30 | i770CA30 | NAT/BLK | Melt Index=2.3g/cm3 ,30% carbon fiber reinforced | Download |

| 12 | PEEK iPEEK® i550CA30 | i550CA30 | NAT/BLK | Melt Index=5g/cm3 ,30% carbon fiber reinforced | Download |

| 13 | PEEK iPEEK® i330CA30 | i330CA30 | NAT/BLK | Melt Index=27g/cm3 ,30% carbon fiber reinforced | Download |

| 14 | PEEK iPEEK® i330FC30 | i330FC30 | NAT/BLK | Melt Index=14g/cm3;Carbon fiber, graphite, PTFE 10% each | Download |

| 15 | PEEK iPEEK® i770FC30 | i770FC30 | NAT/BLK | Melt Index=2.5g/cm3;Carbon fiber, graphite, PTFE 10% each | Download |

| 16 | PEEK iPEEK® i770FE20 | i770FE20 | NAT/BLK | 20% PTFE reinforced | Download |

| 17 | PEEK iPEEK® i330CA15 | i330CA15 | NAT/BLK | 15% carbon fiber reinforced | Download |

| 18 | PEEK iPEEK® i550CA15 | i550CA15 | NAT/BLK | 15% carbon fiber reinforced | Download |

| 19 | PEEK iPEEK® i770CA15 | i770CA15 | NAT/BLK | 15% carbon fiber reinforced | Download |

| 20 | PEEK iPEEK® i330GL15 | i330GL15 | NAT/BLK | 15% glass fiber reinforced | Download |

| 21 | PEEK iPEEK® i550GL15 | i550GL15 | NAT/BLK | 15% glass fiber reinforced | Download |

| 22 | PEEK iPEEK® i770GL15 | i770GL15 | NAT/BLK | 15% glass fiber reinforced | Download |

| 23 | PEEK iPEEK® iFC327 | iFC327 | NAT/BLK | Special for automobile gear, urea pump | Download |

2024 © Copyright DONGGUAN REDSPOT TECHNOLOGY CO.,LTD. All rights reserved.